-

Call Us On:

+86-577-61675999

+86-15355776033 -

Send us a Mail:

- Get a Quote

+86-577-61675999

+86-15355776033

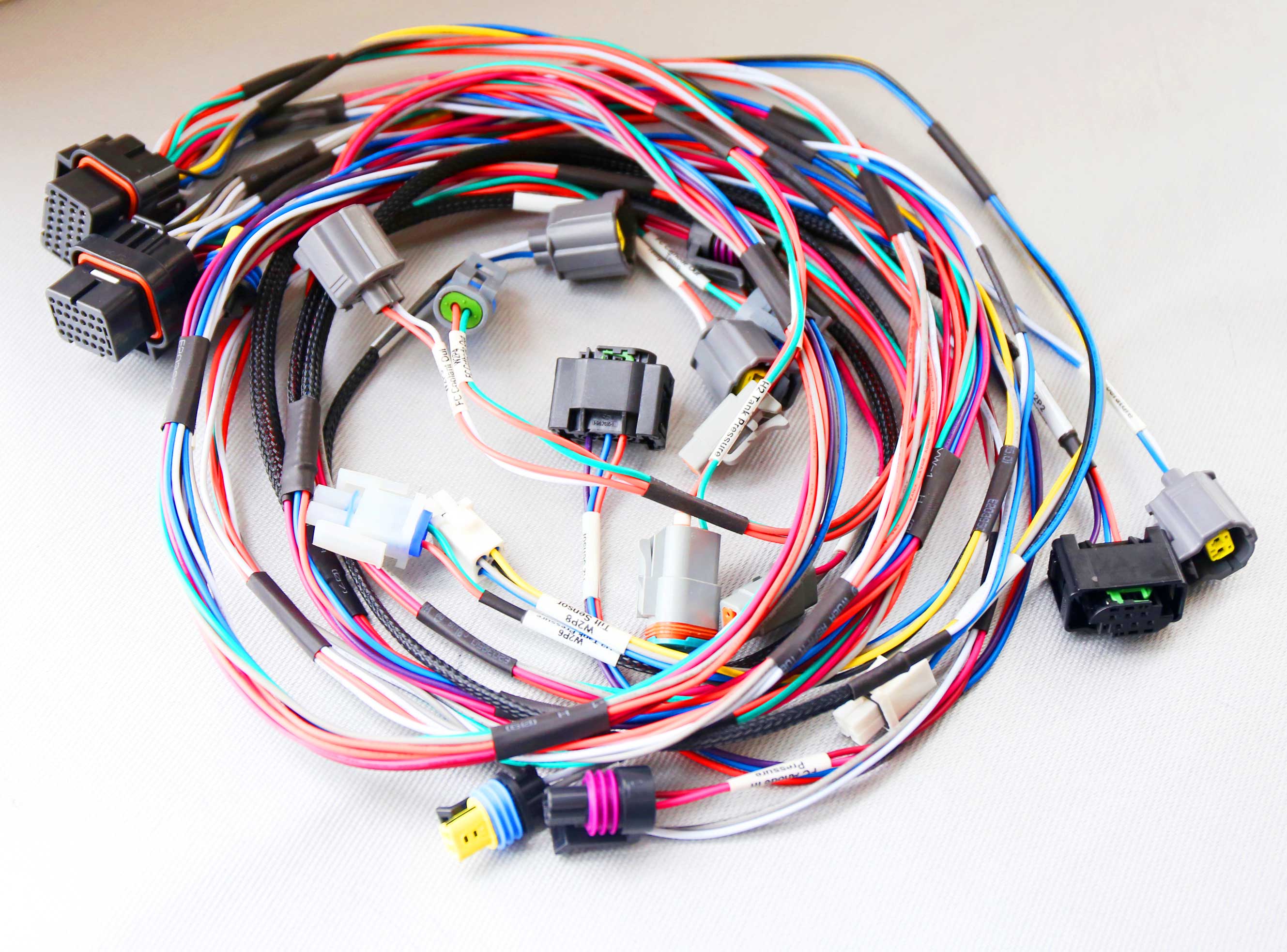

In today’s global economy, automation is essential for wire harness

manufacturers in providing uniformity and consistency that can ensure product

quality. While many aspects of the wire harness production still involve

manual assembly, one vital step in wire harness assembly can be accomplished

efficiently through automated equipment and processes. Cutting, crimping,

and stripping machines offer high speed & reliable solutions for wire

harness manufacturers. The machines can cut wire to length, easily strip

both ends, apply the pins and perform pull-force testing as established in the

pre-setup program.

Why Automate?

The capability to perform wire and cable processing by utilizing fully

automated machinery to cut, strip, and terminate wires and cables is efficient

and cost-effective. The process ensures precision and high repeatability

necessary for stripping with different insulation materials, and in achieving

consistent cutting quality and dimensional accuracy for processed

conductors. The prime benefits of such automated solutions is the

reduction of labor hours to assemble harnesses, an increase in productivity,

and cutting wire-related failures by half. But there is more...

Automation is about combining control systems and technology to replace

continuous human physical and mental labor in assembly and engineering,

allowing human interaction to be applied to more creative, innovative,

operational, and technical processes. Automation benefits manufacturers in

applications where a high degree of precision and accuracy is required.

Quality Control

Automated cutting, stripping, and crimping machines offer process monitoring

that optimizes quality control while components are being made. Monitoring

is fully integrated into the system—crimp force monitoring, seal monitoring,

splice monitoring, as well as a detection system to monitor for wire end and

knots—even comprehensive sorting of the good from bad components. The

system performs at high speed, with efficiency and reliability, and ensures

that all processes of cutting, stripping and terminating are to exact

specification. Fully automated crimping machines are also capable of

twisting and tinning wires to a wide range of lengths and cross sections, and

perform processing options such as full tinning, or tip tinning.

For more information