-

Call Us On:

+86-577-61675999

+86-15355776033 -

Send us a Mail:

- Get a Quote

+86-577-61675999

+86-15355776033

The market for automotive wiring harnesses has reached 100 billion. The development of traditional automobile wiring harness is relatively mature, and it is closely integrated with the OEM. It is a labor-intensive industry, and the value of the harness for passenger cars is 2500-4500 yuan.

High-voltage harnesses are another high-growth sub-sector of new energy vehicles. At present, the new energy vehicle harness system is worth 5,000 yuan, the high-voltage harness is 2,500 yuan, and the market is over 10 billion.

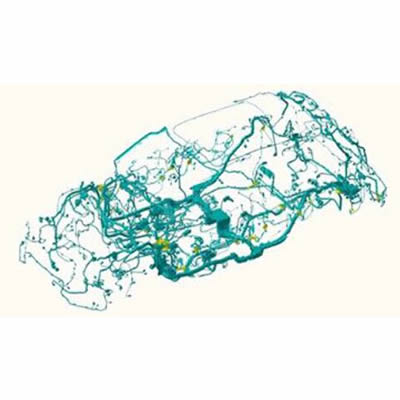

The traditional path of electricity and data is essential. The car harness is like the blood and nervous system of the human body. It runs through all parts of the car and connects all the electronic components to transmit power and data.

The safety reliability requirements of high-voltage harnesses for new energy vehicles are higher. 600V high voltage architecture requires wiring harness: high voltage, high current, high protection level, electromagnetic shielding, insulation, high temperature resistance and high durability. Industry status and future trends:

1. Low-voltage harness components are numerous and miscellaneous, 70% artificially produced resulting in lower gross profit and production efficiency. China's own brand wire harness factory has a large number, small single scale, low concentration, and is in the rising stage of development. The future direction of development is to continuously improve the level of automation, improve efficiency and gross profit margin.

2. The high-voltage harness has fewer parts and components, and the complexity is lower, but the price is high and the gross profit margin is much higher than the low-voltage harness. Chinese enterprises rely on the rapid development of domestic new energy vehicles to seize the market. In the future, the trend of scale-up will be concentrated in the wire harness factory, and the gross profit and quality of the products will be improved.

3. In 2017, China's auto connector market will be about 18 billion yuan, up to 27 billion yuan in 2025. The increase is mainly contributed by high-voltage connectors. Domestic manufacturers have applied high-voltage and high-current connectors in other industries to electric vehicles, and quickly seized the market to take the lead. The next step is to gradually develop a complete product line, enhance their competitiveness, and strengthen the binding relationship with OEMs.

4. Due to the convenience of car body wiring and the high temperature safety, high-pressure silicone rubber cable is the future development direction. At present, foreign manufacturers have no production line in China, and the automotive silicone wire is imported, with long delivery period and high price. Domestic manufacturers are stepping up development to compensate for gaps in technology and capacity.

For more information